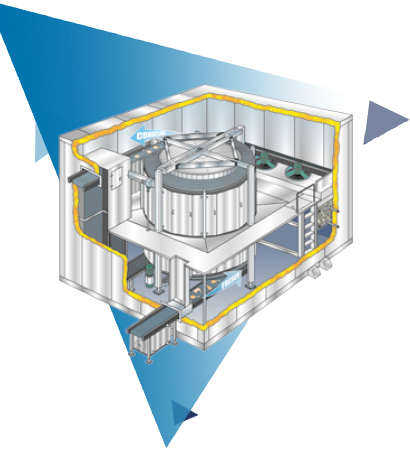

The IQF system is widely used in the food industry for individual freezing of fruits, vegetables, potatoes, red meat, fish, chicken, processed foods, among many others. The air at low temperature and high speed makes the food reach -64° F in a short period of time and steadily.

This equipment generally works with recirculated ammonia in two stages or in an economized stage with Vilter screw or piston compressors, it is also possible to supply them to operate with CO2 or freon.

IQF individual freezing systems and refrigeration equipment are calculated and designed specifically for each client, taking into account the type and characteristics of the product, the flow (Kg/h) and the intake temperature.

100% RELIABLE PRODUCT

12 MONTH WARRANTY

More Advantanges

Foods that are frozen in IQF retain their organoleptic properties (texture, smell, color and taste) for much longer than with other freezing methods. Being a fast process, food will not be affected by macro crystals that break cell walls and cause water spills and loss of micronutrients, especially in products such as chicken and meat.

These freezing systems are heavy-duty and are designed to operate 24 hours a day throughout the week. They are specially manufactured for continuous and constant production processes. They can be installed in line with the production process.

According to the product and the level of freezing (superficial or deep) that the user requires, it is possible to vary the band speed to decrease or increase the time of permanence of the product within the IQF, this is possible thanks to the control system and the heavy-duty reducer that is supplied with the equipment. The freezing times compared to static tunnels and trolley freezer are much more reduced.

The IQF supplied by Alfrio are the most robust and heavy-duty on the market, the conveyor belt moves on an independent structure made of stainless steel, this system ensures that the belt will not collapse or fall due to an additional load of product or clogging generated by the same product. Other systems use self-supporting bands (without support structure) that tend to collapse, generating long unscheduled plant stops and seriously affecting the production process.

Walls, ceiling, floor, electrical panel and other components are manufactured in stainless steel for a longer duration and asepsis.

For poultry applications, the IQF supplied by Alfrio counts on the entrance with a curtain or cold air knife that receives the product to immediately seal the pores of the chicken prey, this notably minimizes product shrinkage and water runoff inside the equipment.