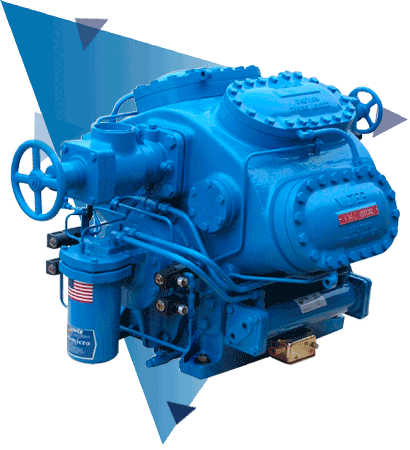

440, 450 and 450XL Vilter piston compressors are highly reliable, efficient and heavy- duty, they are American made and have been represented by ALFRIO for more than 40 years. Installed worldwide in leading bottling companies of beverages, poultry, fish, cattle, dairy, refrigerators, breweries, chemical industry, ships and many others.

These compressors can work with ammonia, freon and even with hydrocarbon refrigerants. They operate in extreme applications with a differential pressure of over 18 bar, driven by pulleys or direct coupling, can operate in a high compression ratio up to 12:1 with certain halo carbonated refrigerants. The sizes range from 2 to 16 pistons and can work in freezing and conservation processes, in one or two stage systems.

The design of Vilter compressors (crankshaft mounted on bearings) minimizes plant shutdowns for maintenance, they have the broadest warranty on the market (up to 3 years depending on the operating conditions).